Does This 3D Printer Farm Make My Butt Look Fat? Or Just My Wallet.

Setting up a 3D printing farm and engaging in micro entrepreneurship seemed like such a stereotypical thing for a libertarian to do. But when the orders for Thomas Jefferson and Trumpy Buddhas started rolling in, it went from a joke to serious business.

My friend Drew White gifted me an Ender 3 Pro 3D printer last year as a way to help me spread the gospel of 3D printing. He's also the donor who gave me an AR-15 during my senate campaign that became infamous for getting me banned from social media, and exposing how Facebook's Sheryl Sandberg was funding my Democratic opponent Claire McCaskill simultaneously. (Sandberg is now under investigation for allegedly exploiting Facebook for personal use.)

Drew probably expected I'd start printing firearms right away, and while I did go through a few test prints of a glock, I realized I needed more experience with the printers before I could do something like that successfully. It's not as easy to make a "ghost gun" as the media or politicians would like you to believe. And anyone who would do it, and doesn't do it well, probably would end up hurting themselves before they'd ever hurt anyone else with it. I will write more about 3D printed firearms in the future. For now, let's focus on the farm.

One day I decided to print a Buddha of George Washington to test the capability of my Ender 3. I posted a photograph online, and was contacted by someone in Jefferson City to ask if they could buy it from me. That's when the lightbulb went off over my head. If the price point was right, the product was interesting enough, and I could produce items fast enough, it would potentially be profitable to open a store for products that I manufactured in home. But one printer wouldn't be enough.

Thankfully, MicroCenter in St. Louis was offering an incredible special on 3D printers exactly like mine. They were only $100 each, but were available to one customer at a time. Thankfully I have friends in St. Louis, and was able to convince four of them to buy one each, and let me buy theirs from them. The process of getting the printers to me was also interesting, in that my friend State Representative Tony Lovasco was able to pick up all the printers from my friends, and ferry them to me in Jefferson City whenever he was in the capitol for session. How's that for a public servant?

Once the 5 printers had all been setup and calibrated, the only thing left to do was print, baby print! Oh, and setup a new website to sell them on. That turned out to be one hell of a situation in itself, fighting Google and Facebook to try to use their tools (mostly unsuccessfully), and finally finding a terrific solution with Shopify that ended up meeting all our needs.

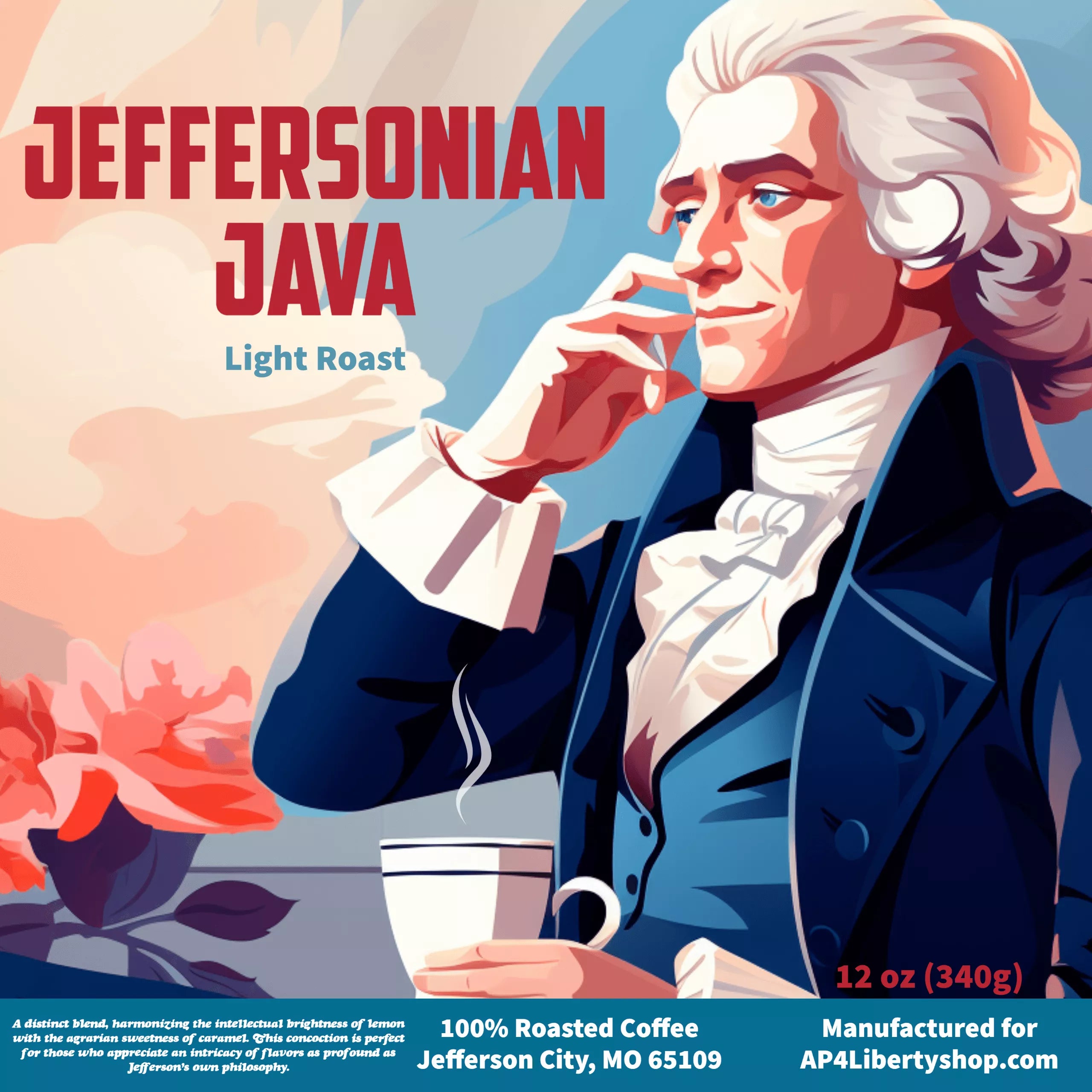

Not only were we able to offer our 3D Printed merchandise through Shopify, but we were suddenly able to use their terrific drop shipping services to create all kinds of new products that people have been snapping up and enjoying.

It's been exciting to see what people have been enjoying and buying. The best part is seeing people sharing their products on social media, which have really contributed to overall sales as well.

Overall, the experience of 3D printing and shipping hasn't exactly been easy to get started. But now that it's up and running, it's become a serious side hustle that has my lovely wife sitting up for a couple extra hours a day sanding little Trumpy Buddhas before she paints them, boxes them, and writes a sweet personal note with each one she sends out.

The process of 3D printing itself has been a big challenge to overcome, but even harder than the actual process of printing is the software side of things. In order to save money and not be forced to contract with 3D modelers through apps like Fiverr, I've been teaching myself how to do edits to models myself, which is a herculean task as well. Thankfully there are plenty of tutorials online to teach you how to do this, as well as free software programs like Blender to allow you to do the time intensive work of creating the 3D models to send to the printer. I've been able to successfully create the Trumpy Buddha, and the Ben Franklin Buddhas myself. I only had to pay someone to create the original Thomas Jefferson Buddha, which cost about $50.

The process of printing can be tedious. Bed leveling, determining the proper temperature, type of plastic, and other settings can be very daunting. The complexity of 3D printing is a double edged sword from a business perspective however. It's just accessible enough for someone like me to be able to use it, but too difficult for most people to be able to use. If it were plug and play, the market would quickly become saturated, and the profitability would go down much faster.

Overall, the business has exploded with traffic and sales in just under a month. The biggest tests now are coming up with new ideas, marketing them appropriately, and finding time to process orders. But with 5 printers running full time, it will be a lot easier to get products to customers in a reasonable time frame. We won't ever be Amazon, but liberty products are a niche that many entrepreneurs have a hard time filling. Libertarians are notoriously difficult to please. There will be a constant challenges to be coming up with new creative ideas to constantly excite their interest and get them to do what a tough economy makes it hard to do: spend money.

Did you enjoy my blog? Have you thought about getting your own 3D printing farm or starting your own business? Leave us your thoughts with a comment below.

- Choosing a selection results in a full page refresh.

!